New Studies on CBFeed

We are conducting studies on safety and effectiveness of our product on 60 heads of cattle under controlled conditions.

We are conducting studies on safety and effectiveness of our product on 60 heads of cattle under controlled conditions.

A conference was held with Uzbekistan's bigest NGO dedicated to poutlry. We presented our product and development plan for the invention in Uzbekistan to its members. Participants showed great interest in the following Q&A session, and plans were made for further cooperation.

Held negotiations with consulting companies during the last months in order to refine our vision of entering the markets of different countries and build partnerships with these consulting companies for further joint work.

Prepared documentation and legal framework for issuing licenses on exclusive use of the invention. Created mechanisms of training, document management, equipment selection, modeling economic efficiency.

With the aim of market research and investment attraction in global markets, a sales team consisting of managers speaking English, French, Kazakh, Russian and Arad languages was assembled.

The new desiccation equipment arrived from Ukraine and started operation. Results show increased quality, improved storage conditions and uninterrupted delivery of the product.

New, more effective method of desiccation of our product was discovered. The optimization scheme based on this discovery promises better quality of the final product and decrease of investment cost. New equipment for the model factory was ordered from Ukraine.

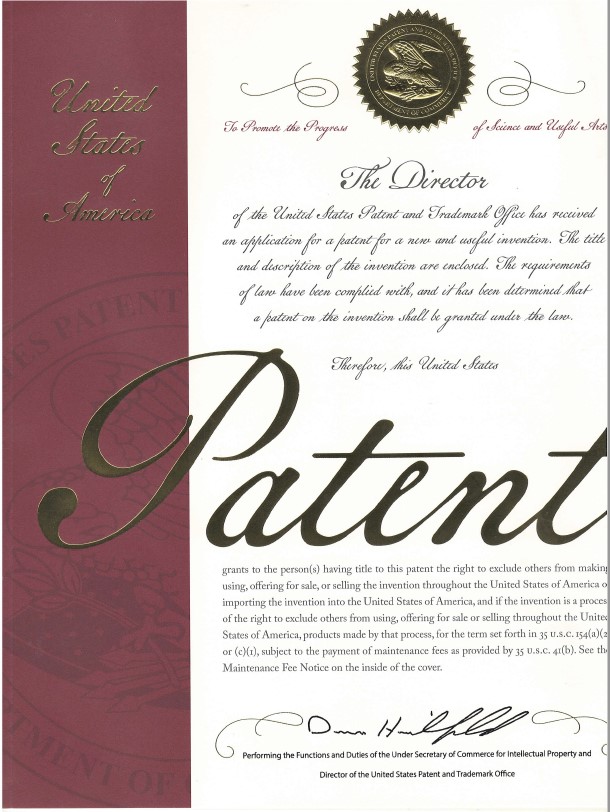

invention patent on new technology for recycling rice husk and converting it into complete animal feed is registered by the United States Patent and Trademark Office.

From spring 2019 to March 2020, in cooperation with "Natural Ventures Tashkent" LLC, "AGROKORM UNIVERSAL" LLC conducted a series of local tests of the products of "Natural Ventures Tashkent" LLC under the patented brand "CBFeed". As a result, it was possible to achieve high economic indicators and it was concluded that the availability of a product with such properties on the market will have a significant impact on increasing the production of poultry meat and its profitability.

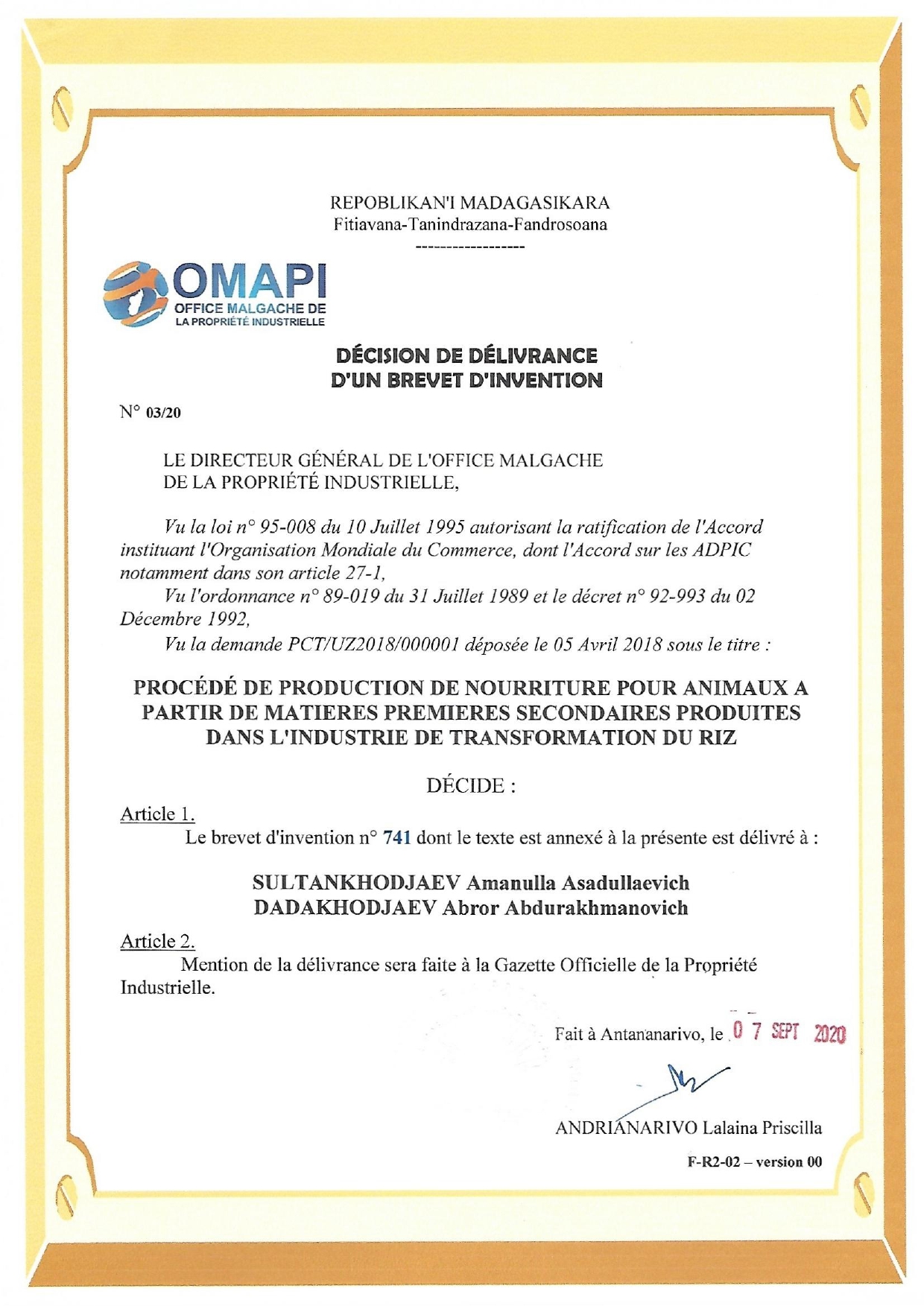

invention patent on new technology for recycling rice husk and converting it into complete animal feed is registered by the OMAPI (Madagascar's authority for intelectual rights).

invention patent (No.34517) on new technology for recycling rice husk and converting it into complete animal feed is registered by National Institute of Intellectual Property of the Republic of Kazakhstan.

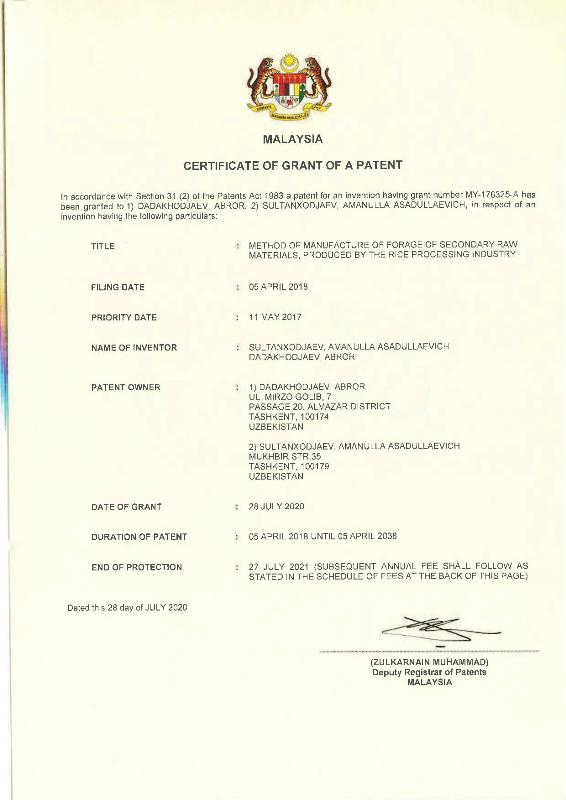

invention patent (No.MY-176325-A) on new technology for recycling rice husk and converting it into complete animal feed is registered by the Registrat of Patents of Malaysia.

invention patent (No.2722100) on new technology for recycling rice husk and converting it into complete animal feed is registered by Federal Service for Intellectual Property of Russian Federation.

We are proud to announce that first full scale CBFeed manufacturing factory is successfully launched in Uzbekistan. This event one more time proves our expectations on industrial application of our newly invented technology for manufacturing our new product - CBFeed.

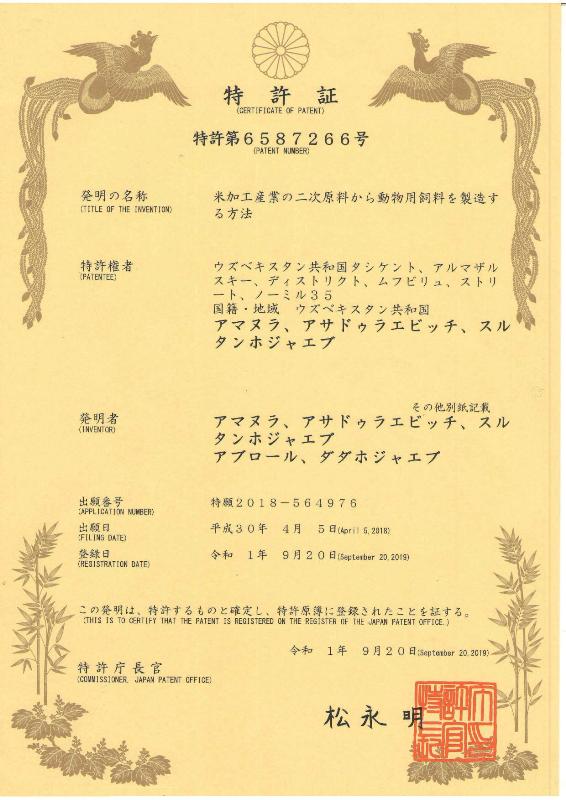

invention patent (No.6587266) on new technology for recycling rice husk and converting it into complete animal feed is registered by Japan Patent Office.

Agency for Intellectual Property under the Ministry of the Republic of Uzbekistan issued first invention patent (No.IAP05799) on new technology for recycling rice husk and converting it into complete animal feed.

In September of 2018, Uzbek - Japanese Center (UJC) has decided to conduct business-forum by gathering 100 Japanese entrepreneurs in one place and invitng there uzbek businessmen as well.

Uzbek businessmen, who are experts from different spheres, planned to attract Japanese investments into Uzbekistan by describing business environment in country for foreigners as well as to build partnership with Japanese businessmen.

In addition, during the Trip to Tokyo, Dadakhodjaev Abror claimed patent in Japan for his know-how technology in animal feed production (CBFeeD).

In the presentation of his business in the forum, Dadakhodjaev Abror, explained his business project on processing of rice husk biologically for production of animal feed. What problems does it solve? What experiments were held? How did he come to this conclusion? - all questions were answered. Consequently, Japanese audience faced his speech as well as project with interest.

Uzbekistan is well-known for its food production and exports to Central Asia. Dadakhodjaev Abror, who owns LLC “Samo Product” and furniture manufacturing company “Art Mebel” said that annual sunny days are more than 300 days in Uzbekistan, and it is worth-mentioning the taste of melon and other fruits. In the packaging process of jelly, the machine and packaging materials are related to Japanese brand. Finally, Mr. Abror showed his desire to work with Japanese companies on the innovative technology to produce feed from rice husk -(AsianEconomicNews, 2018).

The purpose of the visit of our company to Italy is to establish business relations with partners. Following the results of negotiations and establishing cooperation with partners, "Olimxon Global" LLC plans to build a plant for the production of Cattle Bio Feed mixed fodder in these countries. Moreover, several factories for the production of animal feeds have been investigated, and all information has been studied in detail by marketing researchers.

Italy, a country with a lot of rice and cattle production. Effective agreements began on the first day of this trip (July 24, 2018), meeting with various companies that produce rice and animal feed in Italy. These companies are Grand Riso, Mundi Riso, Agrover and others. Most of them, mainly, are engaged in the production of rice and helped to clarify the results of all marketing research conducted in Uzbekistan. All companies expressed their interest in joint cooperation to promote this innovative technology and establish close and mutually beneficial relations. Based on the results of the analysis and marketing research, future partnerships will be held with them in the near future.

To summarize, the trip to Italy was also important, as we received a lot of necessary information. Relations are maintained and in the future we plan to bring our technology to Italy. The ongoing research indicates that there is great potential in this country for the implementation of our technology and achievement of the goals.

The main purpose of the trip to Japan is to find business partners ready to cooperate and build a plant for the production of mixed fodders with LLC "Olimxon Global", as well as familiarize with animal feed factories for a clearer presentation of the situation in the country and clarify the results of marketing studies that were conducted remotely from Uzbekistan.

Production meetings and trips lasted 6 days. During these few days in Japan, official meetings have been planned with different companies - rice plants, animal feed producers, and private cattle farms. Farmers in Japan took this new business as one of the treatment options and expressed interest in using this animal feed as an experiment. Most of these farms are located in the Nagoya region, and the rice-producing companies in the Fukushima region.

In conclusion, the trip to Japan was extremely useful and effective for future business. In fact, the interest of foreign companies informed about the opportunities for the development of this business at the international level. Tight negotiations are underway with large Japanese companies to open several factories in Japan. Current research and positive feed analysis results increase the possibility of achieving all the discussed plans.